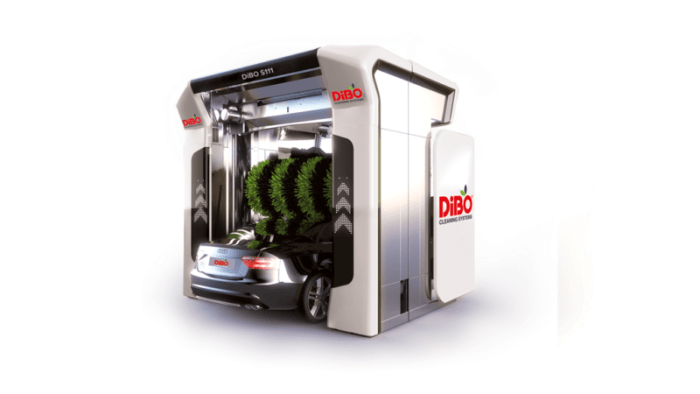

DiBO S111

Advanced technology for a lasting success and reliability

Product specifications

Structure

- Galvanized and painted steel frame

- ABS claddings *

- Direct gantry drive with inverter

- High resistance aviation type rivets

- Stainless steel bolts

Vertical brushes

- Galvanized steel single beam guide rail

- Electrical motion with inverter

- Double brushing on front and rear of the car

- Double tilt and locking by means of cylinder

- Electronic power control

Horizontal brush

- Electrical lifting with inverter

- Electronic power control

- Stainless steel guide rails

Intermediate mobile arch

- Automatic parallelogram extension movement

- Stainless steel horizontal contouring element to dispense wax. Adjustable on 3 positions for high upper pressure

- Electrical lifting with inverter

- Stainless steel guide rails

- Support for fixed side high pressure

* Optional

Drying

- Horizontal stainless steel contour blade, adjustable on 3 positions

- Electrical lifting with inverter

- Stainless steel guide rails

- Side drying 2 electric blowers with tilted blades

- Fall arrest safety system

Standard equipment

- Hydraulic system with dedicated solenoid valves and piping

- Hydraulic system with solenoid valves and special manifolds

- Shampoo dosing pump

- Wax dosing pump

- 2 Single wall festoon cable loop supply

- Control with display and wall button board

- Self-Service arrangement fully integrated in the machine's electronics

Standard full specifications

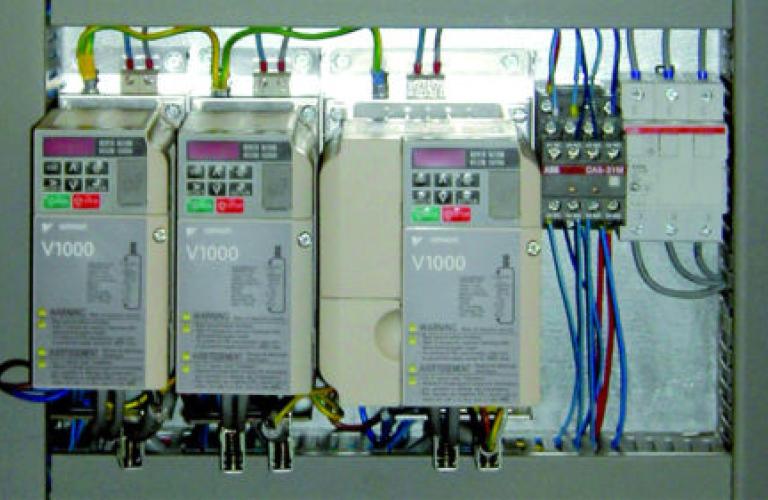

Seven frequency converters

The seven frequency converters deliver a rapid smooth pass, for a precise wash on every part of the vehicle.

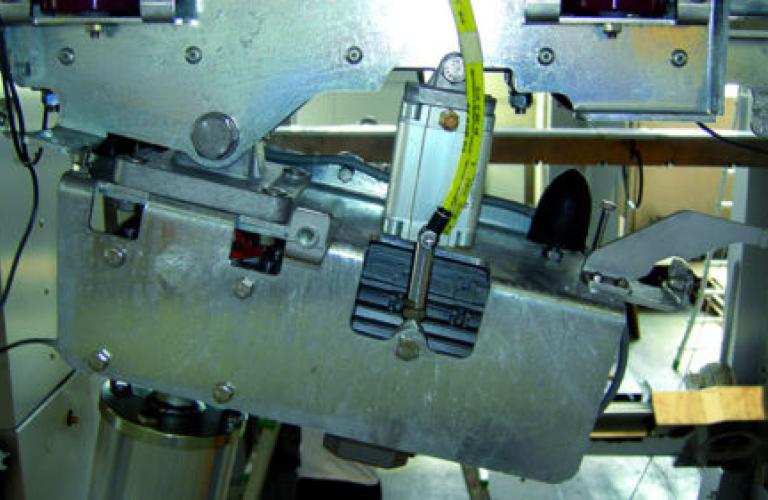

Drive and lift sensor

Measurement of movements with a double sensor which ensures maximum precision and reliability.

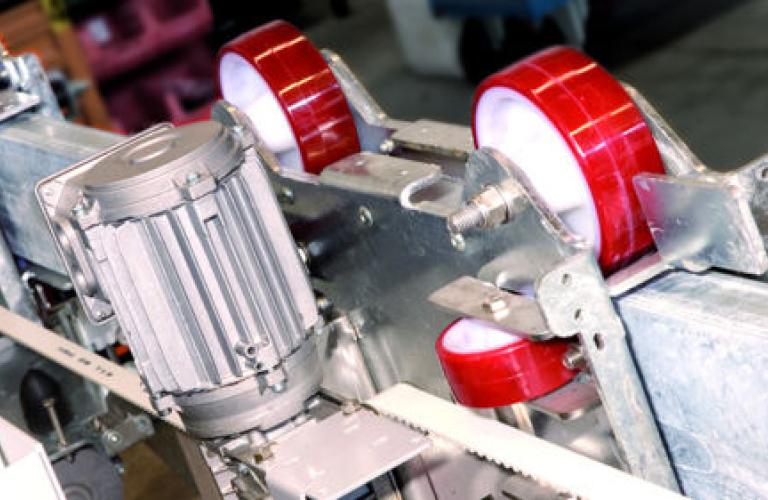

Low maintenance thanks to self-lubricating materials

Innovative materials for smooth and silent movements that also require no lubrication or maintenance.

Security

Lifting belt loosening alarm. Blade anti-fall locking system on drying.

Wax application

The wax is applied using a contour following wax arch and laterally delivered by nozzles positioned close to the vehicle sides, for a perfect water-repellent effect.

Intermediate gantry

Third mobile gantry emerging from the first gantry on an extension system. The intermediate gantry incorporates high pressure and wax application features.

Perfect drying in only one passage

Stainless steel horizontal blade following the vehicle profile, tilting in 3 positions. Inclined side vents. Four electric blowers 5,5 kW/each.

Sensitive side brushes

Tilting side brushes, electronically controlled, perfectly adapting to the profile of the car.

A wide range of accessories, a few examples:

High pressure system

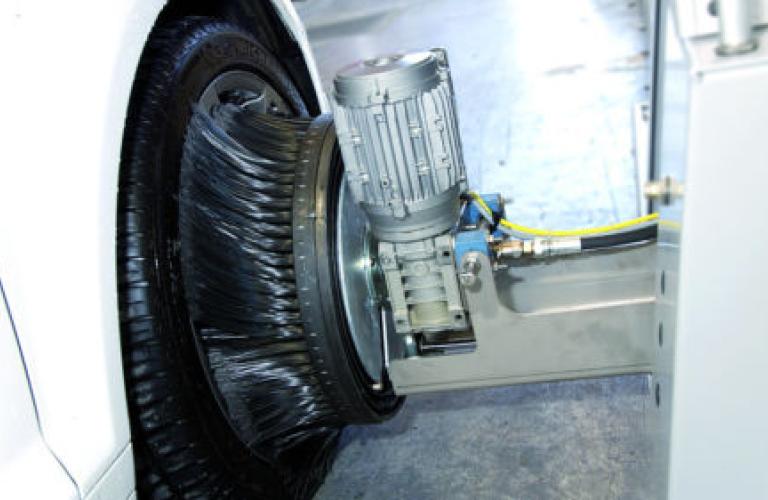

Wheels

Tilting wheel washer with fully integrated rotating high pressure, for a thorough cleaning of rims, wheel arches and sills.

Fixed lateral

- Located on intermediate mobile arch.

- Advanced position for a perfect pre-wash.

Horizontal contour following

- Located on intermediate mobile arch.

- 3 positions tilt optimizing water impact on vehicle’s body

- Advanced position for a perfect pre-wash.

Stainless steel wheel washer:

Wheels

The reversal of rotation and inclination of the brush allows a thorough cleaning of the rims of every dimension.

High pressure pump system:

- Choices of 42, 84 or 126 liters high pressure pumps system, for a powerful pre-wash.

- Available in insulated outdoor cabinet or in frame for technical room.

LED traffic light integrated in the gantry leg:

- Wide traffic light with LEDs, sliding display.

- Perfect also in bright light conditions.

Carlite Brushes:

- New, light and softer in contact with the bodywork.

- High pressure prewash recommended.

Textile:

- Extremely thorough washing and exceptional polishing from this premium option.

- Long lasting.

- High pressure prewash recommended.

Photocells’ Barrier (Optional)

Thanks to the photocells’ barrier it is possible to detect any shape of the vehicle, maximizing the contact of the horizontal brush and the passage of the drying blade.

High precision of detection

Automatic detection of particular shapes (Pickup, Skibox, Lightbars, etc.)

High Speed Detection

First pass of Drying Gantry up 20 m/min.

High Smoothness of Functioning

Drying blade - Horizontal brush

Horizontal High Pressure.